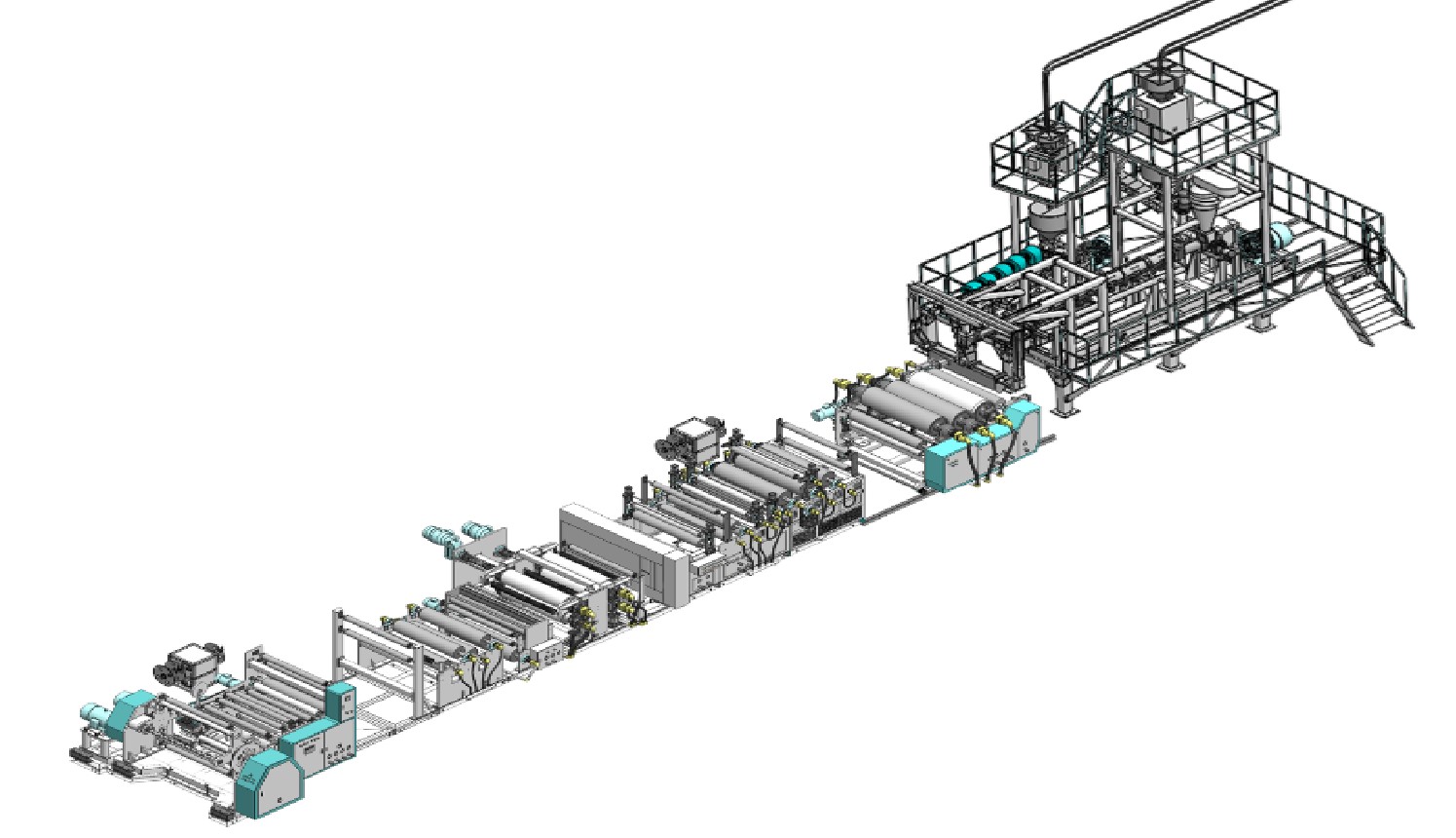

★ The stone paper production equipment adopts the composite flow/calendering production process: Ingredients, blending, extrusion to produce special masterbatch, and then through extrusion, calendering, stretching, cooling, surface treatment, coating, slitting and winding is the base paper. High production efficiency, good product quality, low production cost, smooth paper surface, especially suitable for printing albums and books. Stone paper product features: The production process of stone paper is simple, with high output and low energy consumption; it does not use plant fibers and does not cut down trees, which can save a lot of wood and protect the natural ecology; it does not need to add chemical raw materials such as strong acid, strong alkali, bleaching agent, and does not discharge waste water, Waste residue and toxic and harmful gases are green products. The product has good mechanical properties, waterproof, moisture-proof, moth-proof, folding resistance, tear resistance, oil resistance, non-toxic, odorless, non-polluting, stable geometric size, high printing definition, good effect, and can be naturally degraded into powder after use. Natural and other characteristics, widely used in gift packaging, packaging, office supplies, decorative albums and…

PC,PMMA,PET plastic sheet equipment 1. Product detailed description The PET transparent sheet production line is designed for APET, PET single-layer or multi-layer sheet, and can also produce PS, PP, PE sheet on the same line. It is a multipurpose machine.PET sheets (APET, PETG, CPET) have the characteristics of good processability, transparency, barrier properties, non-toxic, odorless, no environmental pollution, and easy to recycle. In terms of food packaging, it is a material that replaces PVC. 2. Device description This equipment, the technology fully absorbs and digests the extrusion technology, the products selected for the main components (such as screws, barrels, rollers, etc.), the energy consumption, intelligence, automation indicators, safety standards, process standards, etc. of the complete set of equipment are all The quality standard of the product has been reached. This series of products has a number of invention and utility model patents, which can replace imported equipment, but have cost-effective advantages. The products produced are widely used in optical, home appliances, construction engineering, decoration, furniture, advertising, handicrafts and other industrial and civil industries. The quality has reached the performance of the product, and we…

EVA, TPU PP, PE Wide Geotetile (Geomembrane) Production Line The line is applied to produce monolayer or multilayer compound film for all kinds of geotextile, non-woven fabric, weaving fabric. Also it can produce geotextile products. Suitable fabrics Unit Geotexile plastic woven fabrics, non-woven fabrics With of mould mm 3300 4500 6300 8300 Laminate layers one fabric one film; two fabrics one film; waterproof sheet Thickness of laminating film Mm 0.2-2.5 Waterproof sheet thickness Mm 0.5-2.5 Motor of extruder Kw 75-250 Embossing roller size Mm 400 500 600 800 Max. compound width mm 3000 4000 6000 8000 Cooling method Circulating water cooling

PVC elastic floor leather equipment It’s commonly called as plastic flooring sheet, feathers: non-toxic, ultra-light, rub wear resistance, high elastic and high shock resistance, skid resistance, Anti-fire, Water-proof, Sound absorption, antibiosis, quick installation and simple construction, environment friendly and recyclable, easy cleaning and maintaining. The production line can produce 800-3000mm PVC floor leather sheet. Floor leather is one of the indispensable floor materials for modern room decoration.It is not only beautiful and practical, but also has the characteristics of sound insulation, moisture-proof, wear-resistant, corrosion-resistant and flame-retardant. It can be used not only on the floor of living room, but also on the wall of kitchen, toilet and wall to replace ceramic tiles.

PE, PP, PS, ABS Sheet and Board Production Line It is mainly used for the production of PP, PE, PS, ABS single layer or multi-layer sheet; the sheets are used to produce thermoforming or injection products. Extruder SJ65—SJ150 Sheet layer Single layer or multi-layer sheet Board width 400-2000mm Board thickness 0.2-2.5mm Max. extrusion capacity 30-500kg/h Production line speed 15m/min

PE strip reinforcement sheet equipment PE strip rib sheet equipment This production line is mainly used to produce the “T” grid sheet with the thickness 2-10mm, width 750-2200mm. 1.About the device Supporting host SJ120-170 single screw extruder Screw aspect ratio (L/D) 33:1 Screw speed (r/min) 73-90 Main motor power (kw) 132-220 Production capacity (kg/h) 400-800 T-shaft width × diameter mm 2000×Φ500 Mirror surface calendering axis speed r/min 0.15-3 Traction speedr/min 0.15-3 Traction power kw 4 Cutting power kw 4 Overall dimensions of the unit (length × width × height) m 45-55×3.5×4.25 2. Features of PE strip rib sheet production line Our company absorbs and digests the latest foreign advanced technology and technology to develop the strip rib sheet production line, which is mainly used for the production of PE strip rib sheets.The various accessories of this production line equipment can adopt world famous brand products, combined with our company's many years of board (sheet) equipment manufacturing technology and experience, to make it more reliable and perfect. The surface of its products is smooth, the size error is small, and it has many advantages…

PVC spinneret carpet extrusion production line PVC silk spray mat production lines of plastic spray silk carpet, also called the polyster beautiful MATS, plastic wire, bubble film composite forming at a time. Product has soft, ageing resistance, easy to clean, easy to use, the advantages of it is mainly used for shops, public places, family, hospital, elevators, stairs, gym, office space. Product USES the environmental protection high quality PVC raw materials, color lasting bright, not easy to fade. Spring wire coil mat design, feel soft and comfortable, easy to clean. Monochromatic silk spray mat need two extrusion machine, a wire extrusion, another sheet extrusion, online composite forming. It is mainly used for door mat, floor MATS, etc. Double color silk spray mat, need three extrusion machine, two sets of extrusion, another extrusion board, synthetic online. Mainly used for the production of car MATS.

PVC decorative sheet and transparent sheet production line 1. Equipment description: The screw is designed with special mixing function and high plasticizing capacity.⊙ The hanger-type die head adopts the design of double throttling for the number of pages, which makes the adjustment of the thickness of the sheet more accurate.⊙ Temperature control ±1 ℃ can precisely control the plasticizing process and the thickness and shape of the plate.⊙ The three-roll calender adopts the horizontal, vertical or 45° inclined type, which can be freely raised and lowered according to the different plastics produced, and the product thickness, width and transparency requirements.⊙ Slicing machine, the plate can be cut to length and the quantity is accurate. The winding table device adopts advanced torque motor, which can adjust the speed and winding tension at will. 2. The products and features that the equipment can produce are as follows: PVC rigid sheet and PVC flexible board: PVC rigid sheet is widely used in blister packaging of hardware tools, electronics, food, medicine, handicrafts and other high-grade printing; PVC flexible sheet is mainly used for automobile plastic…

EPE foam cloth production line 1. Application of EPE foamed cloth Polyethylene foam cloth is also known as pearl cotton. Pearl cotton is a new type of packaging material. Compared with traditional materials, it has better performance, low cost, high grade and beautiful appearance. It is an ideal substitute for traditional packaging materials. Pearl cotton is widely used in Packaging of household appliances, precision instruments, bicycles, polyurethane furniture, high-grade leather shoes, glass, high-grade porcelain and other products. According to customer needs, the surface of the foamed cloth can be covered with a film, and the product can be thickened to 100mm with a thickener. 2. Equipment features: The EPE foaming cloth unit adopts advanced single-machine foaming process, the product has high foaming rate, energy saving and high efficiency, adopts explosion-proof motor, German Siemens frequency conversion speed regulation and Japanese Omron intelligent digital display instrument, automatic control, safe and stable operation, convenient operation, precise Select high-quality accessories at home and abroad, the quality is stable and reliable. 3. Technical parameters machine type SM-EPE 90 SM-EPE105 SM-EPE120 SM-EPE150 SM-EPE170 Product width (mm) 1000-1400…