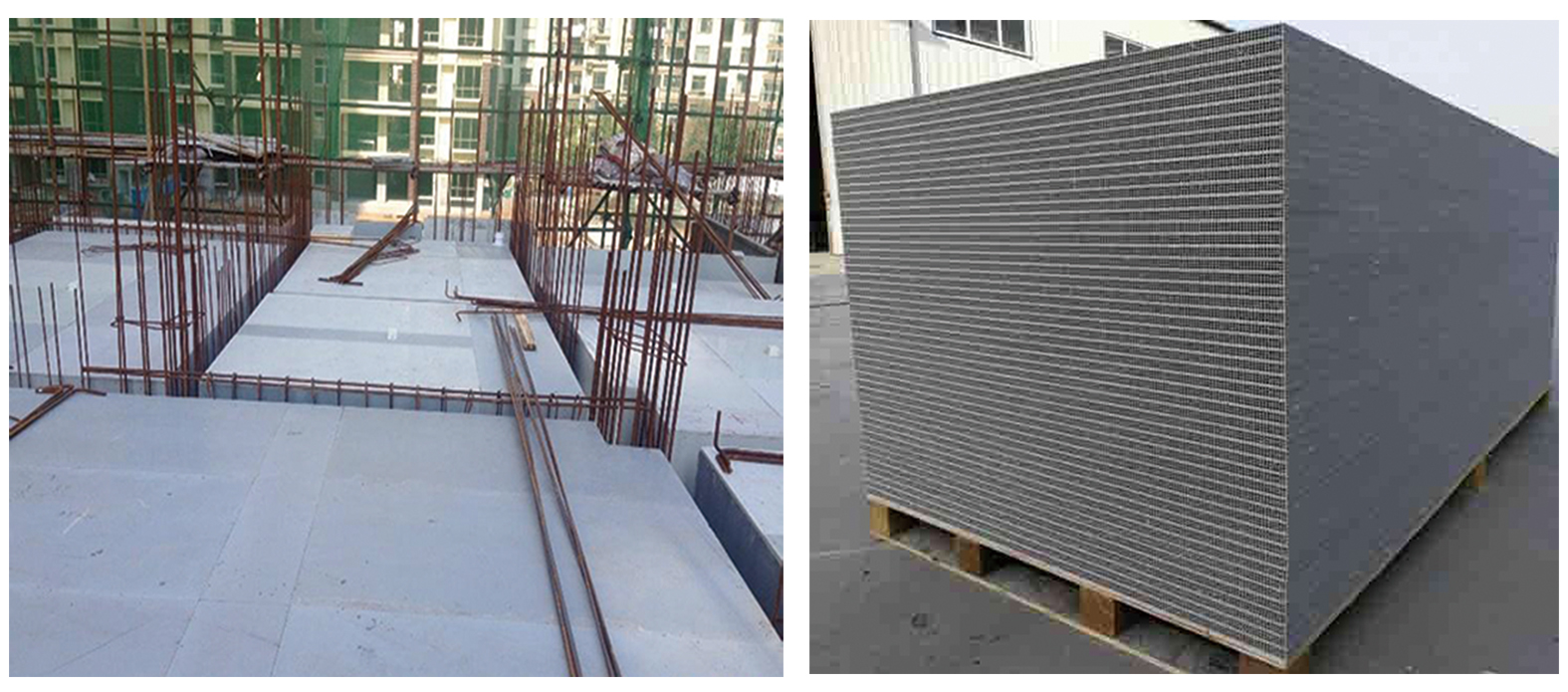

1. Compared with traditional formwork, PP hollow building formwork has the following characteristics:

A. Good water resistance. Even if it is completely soaked for a long time, it will not deform or rot due to moisture.

B. It is not compatible with cement, not sticky, easy to demould after construction, and will not deform due to the adhesion of cement.

C. The hollow building formwork can be reused up to 50-100 times.

D. When processing the template, the surface of the template can also be pretreated to obtain the desired wall pattern.

E. Light weight and convenient construction. Improve construction efficiency.

F. Long service life, easy to recycle, and many times of repeated use.

G. Leftover materials and waste formwork can be crushed and reprocessed into new formwork, which meets the requirements of “green environmental protection”.

H. Good thermal insulation, which is conducive to shortening the construction period.

I. Various treatments can be performed by adding wood methods, and welding can also be performed, which can be processed flexibly on the construction site.

J. Stable weather resistance. The hollow building formwork has anti-aging, acid and alkali resistance, corrosion resistance and small expansion coefficient.

2. Introduction of PP hollow building formwork production line:

The PP hollow building formwork production line is successfully developed by our company by absorbing and digesting foreign advanced extrusion technology and independent invention and innovation. The surface of its products is smooth and clean, and the size error has many advantages such as nailing, planing, corrosion resistance, and strong flame retardant.