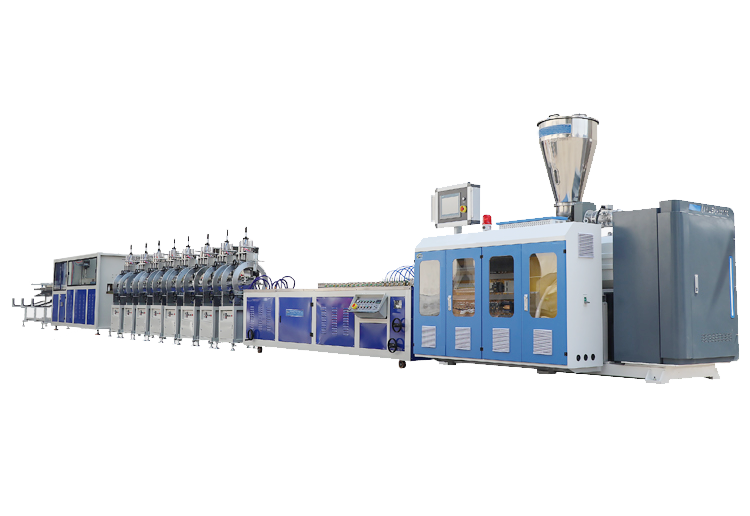

PVC profile and PP, PE, PVC WPC profile production line:

1. Product introduction:

Using specially designed screw barrel, mold and extruder processing production technology to produce wood plastic products. The extruder can be directly extruded by two-stage mixing in a single machine, or it can be extruded in two steps after granulation, which saves electricity and space, has high output, and has stable extrusion pressure. The residual water in the powder makes the feeding section of the main machine more substantial; the plasticizing and mixing effect is good. The optimized screw design makes the shear small, it is not easy to cut the wood fiber, and the material stays in the machine for a uniform time. The screw barrel is treated with bimetal, which is wear-resistant and corrosion-resistant, and its service life is greatly extended.

This production line can produce PE, PP or PVC wood-plastic profiled products. The products are sturdy and durable, and have the advantages of both plastic products and wood products. It not only overcomes the shortcomings of easy deformation of plastic products, but also overcomes wood products that are easy to corrode, moth-eaten, etc. The disadvantage of short service life, it is mainly used for pallets, packing box boards, floors, outdoor decoration materials, etc., and has a wide range of uses; High addition of wood flour and plant fiber (up to 50-75%);

2. Main technical parameters

| Production line model | XQ180 | XQ240 | XQ300 |

| Maximum profile width (mm) | 180 | 240 | 300 |

| Auxiliary total power (kw) | 18.7 | 27.5 | 33.1 |

| Cooling water capacity (m3/h) | 5 | 7 | 7 |

| Compressed air pressure (MPa) | 0.6 | 0.6 | 0.6 |